19 Products

Polytetrafluoroethylene (PTFE) or 'Teflon' is used in applications where exceptional chemical resistance, high heat resistance (260˚C), self-lubrication and electrical resistance is required.

High-performance polymer-plastic PTFE (polytetrafluoroethylene) components and fasteners are commonly used in the oil and gas industry due to their excellent chemical resistance and durability. PTFE is a high-performance polymer that is known for its exceptional resistance to heat, chemicals, and abrasion. These properties make PTFE components and fasteners ideal for use in harsh and demanding environments, such as those encountered in the oil and gas industry.

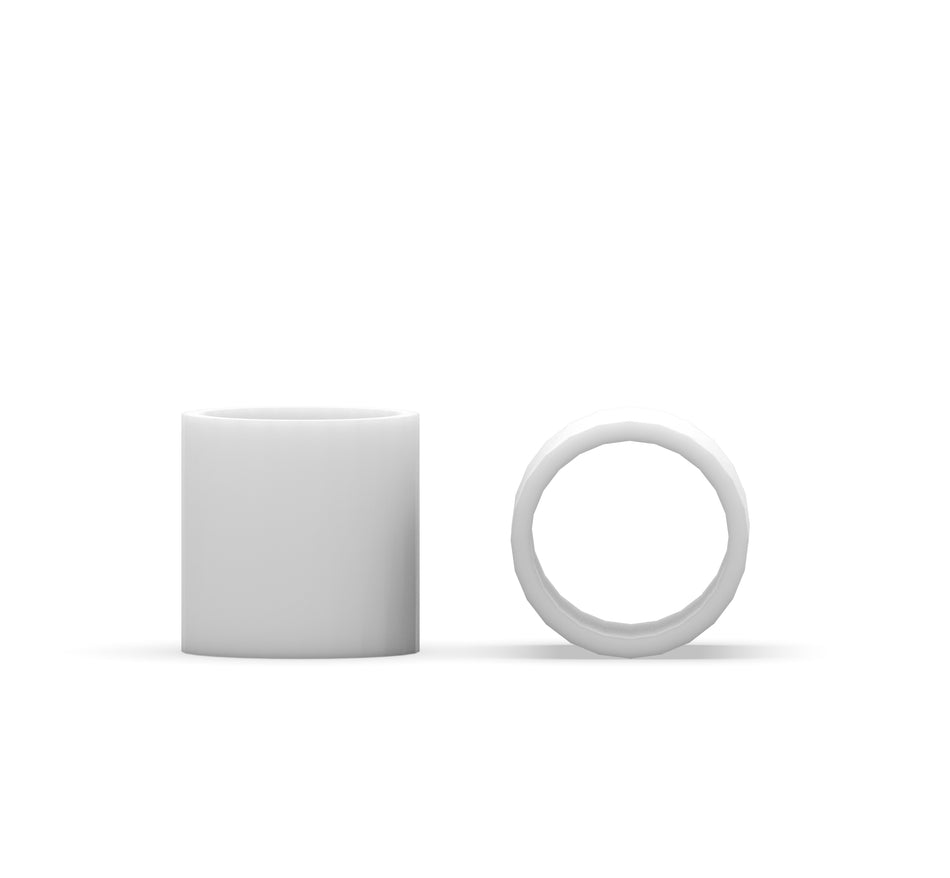

PTFE components and fasteners are used in a variety of applications in the oil and gas industry, such as sealing and fastening equipment and piping systems. One of the primary uses of PTFE components is as seals and gaskets. PTFE gaskets provide a tight seal that prevents leaks and reduces the risk of equipment failure. PTFE components are also used as fasteners, such as screws, bolts, and nuts, due to their exceptional strength and durability.

PTFE components and fasteners are highly resistant to corrosion and chemicals, making them ideal for use in the harsh and corrosive environments encountered in the oil and gas industry. They can withstand exposure to a wide range of chemicals and are unaffected by many acids, bases, and solvents. PTFE is also non-reactive, which means that it will not react with other chemicals, making it an ideal material for use in chemical processing and transportation applications.

PTFE components and fasteners are also resistant to high temperatures, which makes them ideal for use in high-temperature applications. They can withstand temperatures up to 260°C (500°F) without degrading or losing their strength. This makes PTFE components and fasteners well-suited for use in the high-temperature environments encountered in the oil and gas industry.

In summary, high-performance polymer-plastic PTFE components and fasteners are widely used in the oil and gas industry due to their exceptional chemical resistance, durability, and ability to withstand harsh and demanding environments. Their chemical characteristics, including resistance to corrosion and high temperatures, make them ideal for use in the processing and transportation of chemicals and in other applications where high performance and durability are required.