157 Products

Why are high temperature resistant polymers needed?

High Temperature Resistant Polymer Materials

Polyimide (PI)

Polyether Ether Ketone (PEEK)

Polyphenylene Sulfide (PPS)

High Temperature Fastener Applications

How is a high temperature resisting polymer created?

What are the benefits of a high temperature resisting polymer fasteners?

What other beneficial properties do heat resistant polymers utilise?

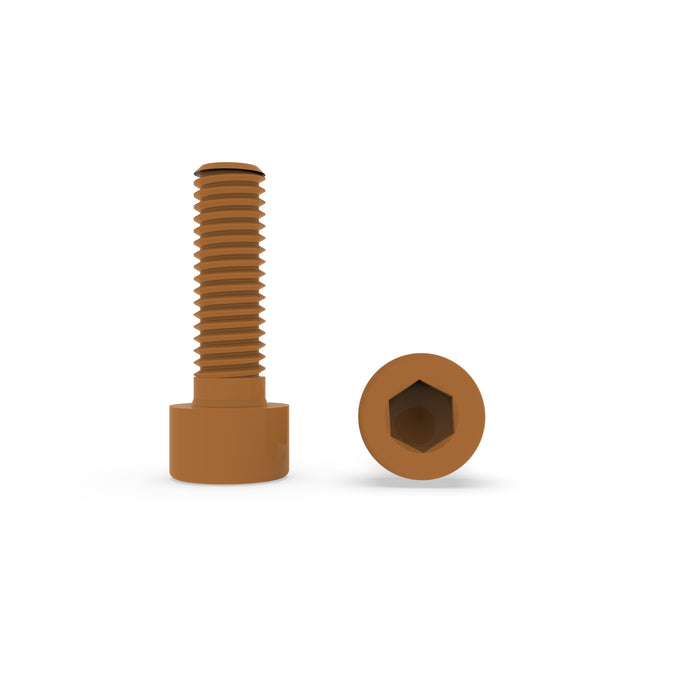

High temperature polymer screws, nuts, bolts, washers, and fasteners are fasteners that are made from polymers that are able to withstand high temperatures. They are used in a variety of applications where high temperatures are a concern, such as in the aerospace, automotive, and energy industries.

There are a variety of high temperature polymers that can be used to make screws, nuts, bolts, washers, and fasteners, including polyimide, polyphenylene oxide (PPO), and polyetheretherketone (PEEK). These polymers are known for their excellent thermal stability, which allows them to maintain their mechanical properties at high temperatures.

High temperature polymer screws, nuts, bolts, washers, and fasteners may be used in a variety of applications where high temperatures are a concern, such as in the construction of aircraft or in the operation of power plants. They may also be used in the manufacture of automotive parts or in the assembly of mechanical or structural components.

Overall, high temperature polymer screws, nuts, bolts, washers, and fasteners are an important component in many applications where high temperatures are a concern, and they are often chosen for their ability to withstand high temperatures without degrading or failing.