234 Products

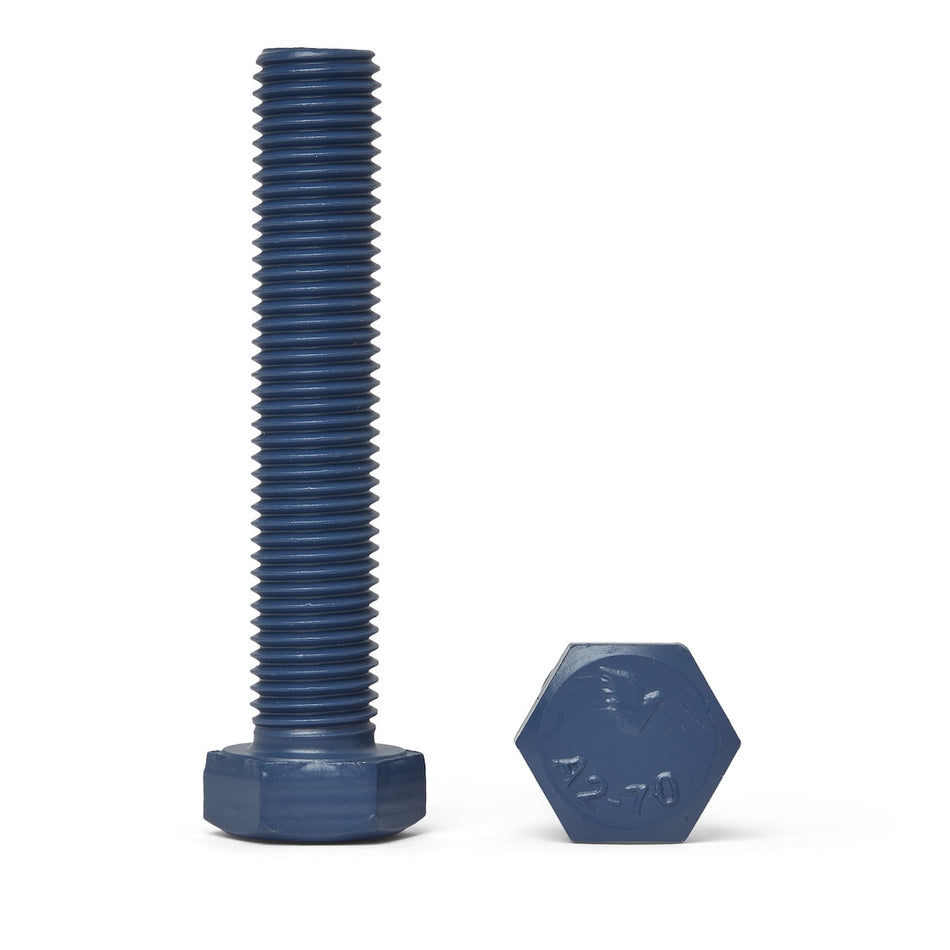

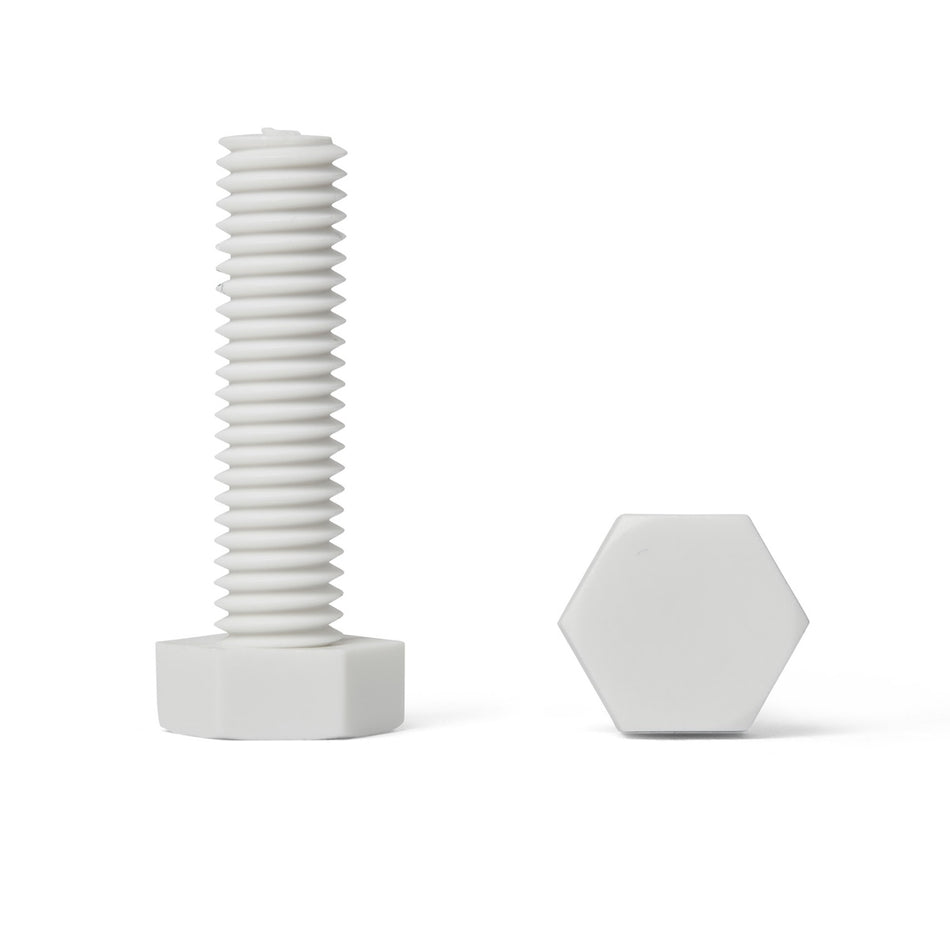

Non-Conductive Polymer Screws, Nuts, Bolts, Washers, and Fasteners

Why are non-conductive fasteners necessary?

Non-conductive polymer fasteners are often chosen for their low electrical conductivity, as well as their other beneficial properties, such as corrosion resistance and good mechanical properties. They can help to improve the safety and reliability of electrical and electronic systems, and they can help to prevent electrical accidents and failures.

Non-conductive materials

Examples of non-conductive fastener materials include:

Polyetheretherketone (PEEK): Is a type of polymer that is made from monomers called ketones. It is a non-conductive material that is known for its excellent mechanical and thermal properties, including a high tensile strength, high modulus of elasticity, and good fatigue resistance. PEEK is often used as a non-conductive fastener material in the aerospace, automotive, and electronics industries.

Polyphenylene Sulfide (PPS): is a type of polymer that is made from monomers called Sulfides. It is a non-conductive material that is known for its excellent electrical insulation properties, good chemical resistance, and high temperature resistance. PPO is often used as a non-conductive fastener material in the electronics and electrical industries.

Polytetrafluoroethylene (PTFE): Is a type of polymer that is made from monomers called tetrafluoroethylenes. It is a non-conductive material that is known for its excellent chemical resistance, low coefficient of friction, and high temperature resistance. PTFE is often used as a non-conductive fastener material in the electronics and electrical industries.

Non-conductive materials are used to make fasteners that do not conduct electricity. These fasteners are used in applications where it is important to prevent the transfer of electrical current between different components or materials. Some examples of non-conductive fastener materials include PEEK, PPS, and PTFE.

Non-Conductive fastener applications

Non-conductive fasteners are used in a wide range of applications where it is important to prevent the transfer of electrical current between different components or materials. Some examples of non-conductive fastener applications include:

Electronics and electrical industries: Non-conductive fasteners are often used in the electronics and electrical industries to secure components in place and provide electrical insulation. They are used to prevent the transfer of electrical current between different components, which can cause short circuits or other problems.

Aerospace industry: Non-conductive fasteners are also used in the aerospace industry to secure structural components and prevent the transfer of electrical current between different parts of the aircraft. This is important to ensure the safety and reliability of the aircraft.

Medical devices: Non-conductive fasteners are used in the production of medical devices, such as pacemakers and defibrillators, to secure components in place and provide electrical insulation.

Industrial machinery: Non-conductive fasteners are used in the production of industrial machinery, such as pumps and motors, to secure components in place and provide electrical insulation.

Non-conductive fasteners are used in a wide range of applications where it is important to prevent the transfer of electrical current between different components or materials. These fasteners are used to ensure the safety and reliability of electronic and electrical devices, as well as to secure structural components and prevent short circuits.

What makes these fasteners non-conductive?

Non-conductive polymers are made by selecting materials with molecular structures that naturally resist the flow of electrical current. Polymers are composed of long chains of non-metallic elements like carbon and hydrogen, which lack free electrons that typically enable electrical conductivity in metals. This lack of free-moving electrons is the key factor that makes polymers non-conductive. During the manufacturing process, the polymer's composition is carefully controlled to avoid introducing conductive elements or impurities, ensuring electrical insulation properties. Additionally, the use of additives or fillers that could disrupt insulation is minimized, further enhancing the non-conductive nature of the polymer. These inherent properties make non-conductive polymers ideal for electrical insulation and electronic applications.

What are the benefits of non-conductive fasteners?

Non-conductive polymer fasteners offer several key benefits, making them highly suited to industries like electronics, electrical systems, and telecommunications. Their primary advantage is electrical insulation, which prevents the flow of electricity between components, reducing the risk of short circuits and improving safety in sensitive electronic equipment. These fasteners are also lightweight, which is particularly useful in industries like aerospace and automotive, where reducing weight improves efficiency. Additionally, they offer corrosion resistance, ensuring long-term durability even in harsh environments, such as outdoor installations or chemical processing plants. Non-conductive polymer fasteners are also chemically resistant, able to withstand exposure to solvents, oils, and chemicals, further enhancing their suitability for industrial applications. Combined with their flexibility and vibration resistance, these fasteners provide stability and protection in dynamic or high-vibration settings, ensuring reliable performance over time in demanding applications.

Other beneficial properties of non-conductive fasteners

Non-conductive polymer fasteners offer additional benefits like thermal insulation, helping protect components from heat transfer, and their lightweight nature reduces system weight, improving efficiency in aerospace and automotive industries. They provide excellent corrosion and chemical resistance, making them durable in harsh environments such as marine, chemical processing, and outdoor applications. These fasteners also offer vibration dampening, reducing wear and stress in high-vibration settings, and their flexibility allows them to withstand mechanical stress without deforming. These combined properties make non-conductive polymer fasteners ideal for industries requiring electrical insulation, durability, and reliable performance.

Non-conductive polymer screws, nuts, bolts, washers, and fasteners are fasteners that are made from polymers that have a low electrical conductivity. They are used in a variety of applications where electrical conductivity is a concern, such as in the electronics and electrical industries, or in environments where electrical hazards are present.

There are a variety of non-conductive polymers that can be used to make screws, nuts, bolts, washers, and fasteners, including polyethylene, polypropylene, and polytetrafluoroethylene (PTFE). These polymers are known for their low electrical conductivity, which makes them suitable for use in applications where electrical conductivity is a concern.

Non-conductive polymer screws, nuts, bolts, washers, and fasteners may be used in a variety of applications where electrical conductivity is a concern, such as in the construction of electrical equipment or in the assembly of electronic components. They may also be used in the manufacture of electrical insulation materials or in the installation of electrical systems.

Non-conductive polymer fasteners are often chosen for their low electrical conductivity, as well as their other beneficial properties, such as corrosion resistance and good mechanical properties. They can help to improve the safety and reliability of electrical and electronic systems, and they can help to prevent electrical accidents and failures.

In addition to their use in the electronics and electrical industries, non-conductive polymer fasteners may also be used in other applications where electrical conductivity is to be avoided.