234 Products

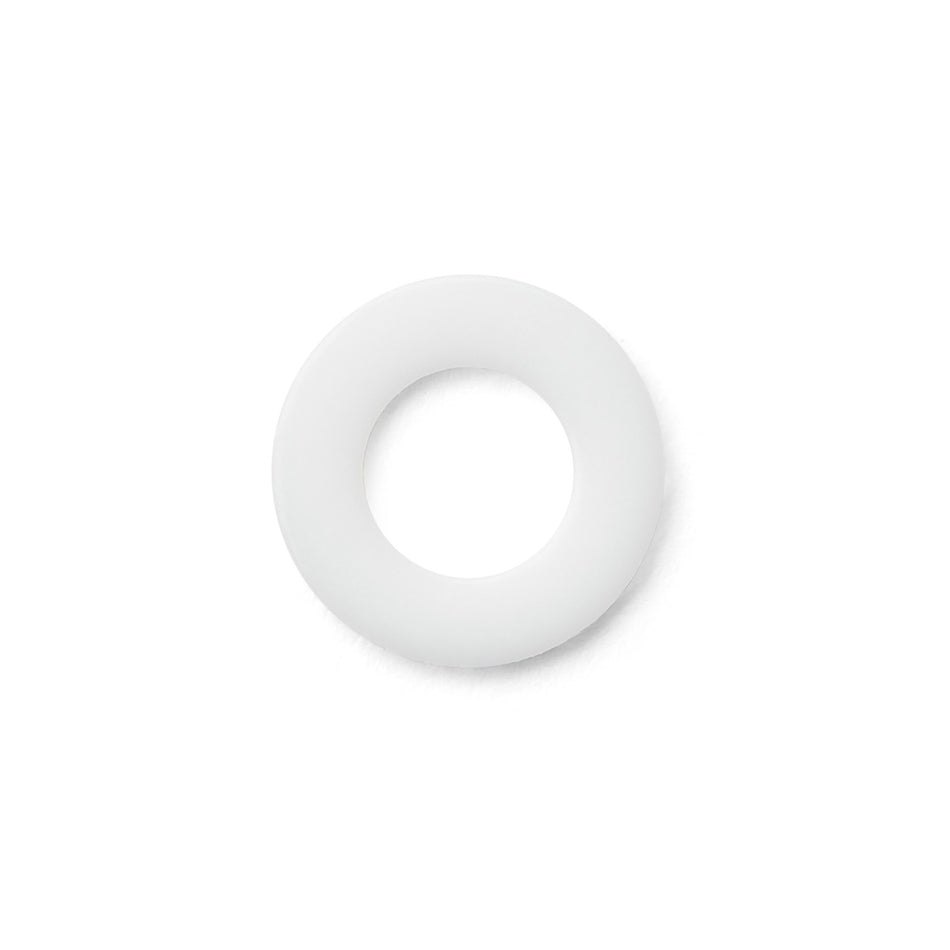

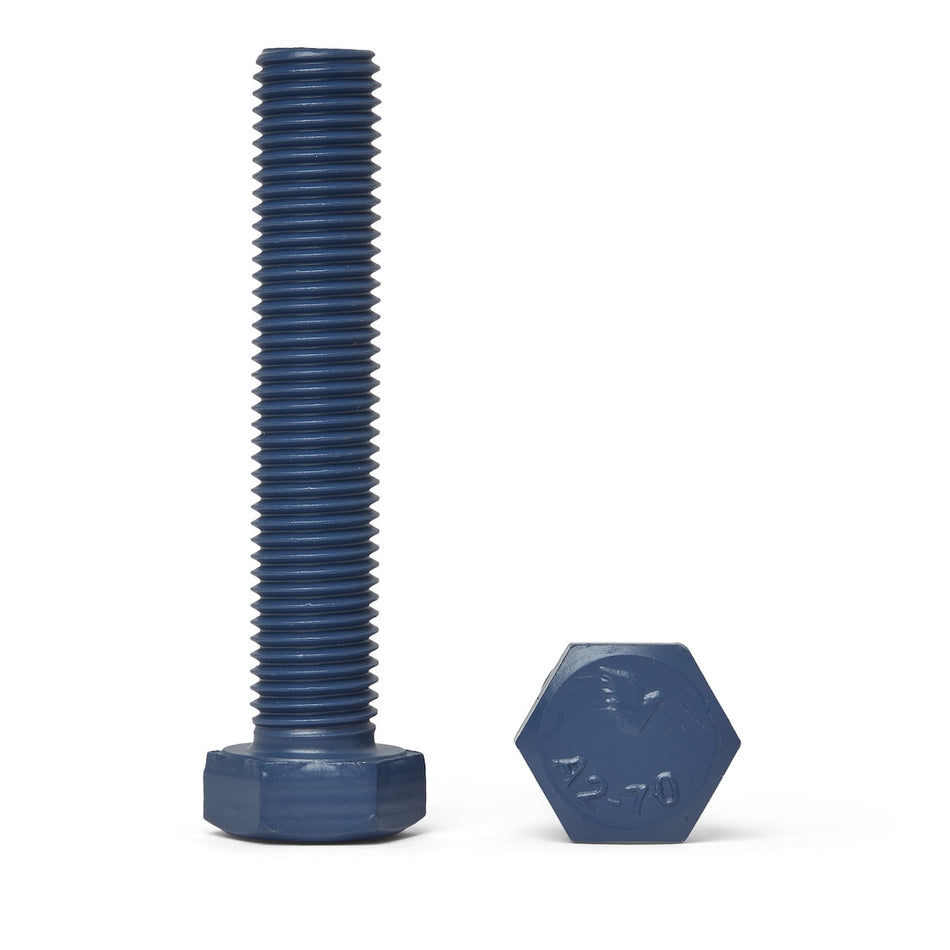

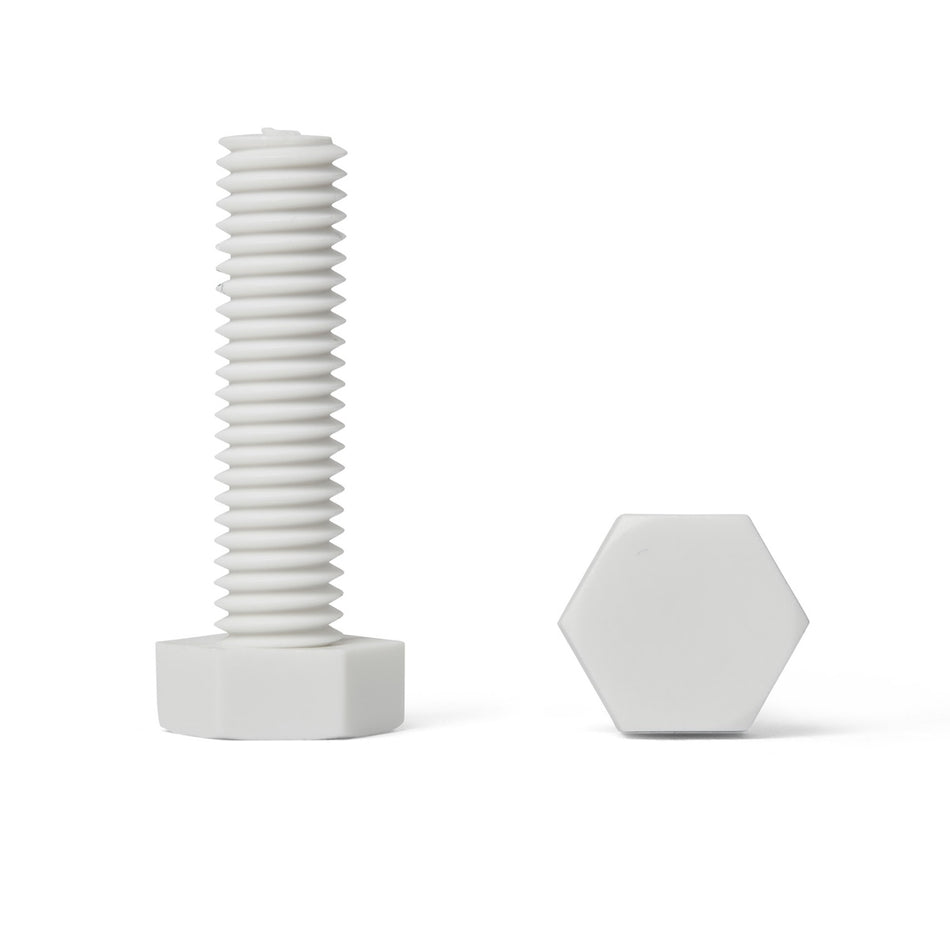

Low Thermal Conductivity Screws, Nuts, Bolts, Washers, and Fasteners

Why Are Low Thermal Conductivity Polymer Fasteners Necessary?

Low thermal conductivity fasteners are an important component in environments that are heat sensitive and cannot have heat transfer between components. There are multiple industries where this applies, which make this type of fastener essential for specific applications

Low Thermal Conductivity Polymer Materials

There are a variety of low thermal conductivity polymers that can be used to make screws, nuts, bolts, washers, and fasteners, including polyethylene, polypropylene, and polytetrafluoroethylene (PTFE). These polymers are known for their low thermal conductivity, which makes them suitable for use in applications where thermal management is a concern.

Some other examples of materials that are used to make low thermal conductivity fasteners include:

Polyether ether ketone (PEEK): Is a type of polymer that is made from monomers called ketones. It has a low thermal conductivity, making it a good choice for use in low thermal conductivity fasteners. PEEK is known for its excellent mechanical and thermal properties, including a high tensile strength, high modulus of elasticity, and good fatigue resistance.

Polytetrafluoroethylene (PTFE): Ia type of polymer that is made from monomers called tetrafluoroethylenes. It has a low thermal conductivity, making it a good choice for use in low thermal conductivity fasteners. PTFE is known for its excellent chemical resistance, low coefficient of friction, and high temperature resistance.

RENY: Is a brand of polymer fasteners that are made from a proprietary blend of polymers. They have a low thermal conductivity, making them a good choice for use in low thermal conductivity fasteners. RENY fasteners are known for their excellent mechanical and thermal properties, including a high tensile strength, high modulus of elasticity, and good fatigue resistance.

Low thermal conductivity fasteners are made from materials that have a low thermal conductivity, which is a measure of a material's ability to conduct heat. These fasteners are used in applications where it is important to minimize the transfer of heat between different components or materials. Some examples of materials that are used to make low thermal conductivity fasteners include PEEK, PTFE, and RENY.

Low Thermal Conductivity Applications

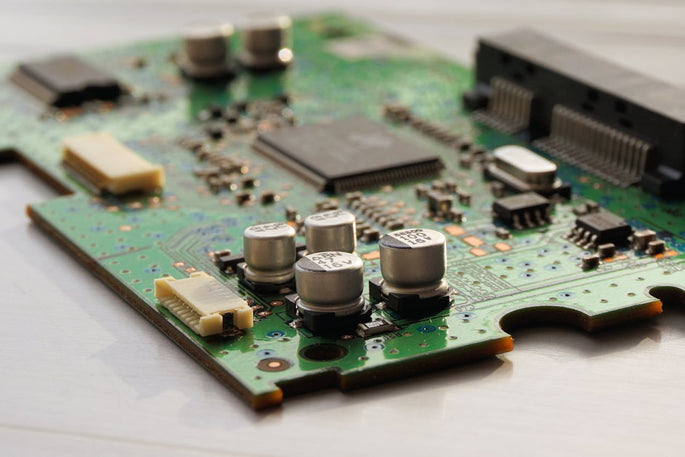

Low thermal conductivity polymer screws, nuts, bolts and washers may be used in a variety of applications where thermal management is a concern, such as in the construction of electronic devices or in the assembly of mechanical components. They may also be used in the manufacture of insulation materials or in the installation of heating and cooling systems.

They are also often chosen for their low thermal conductivity, as well as their other beneficial properties, such as corrosion resistance and good mechanical properties. They can help to improve the performance and reliability of equipment and systems in environments where thermal management is a concern, and they can help to prevent overheating or to dissipate heat effectively.

What makes these polymers low thermal conductive?

Low thermal conductivity polymers are made by selecting specific chemical structures that inhibit the transfer of heat. The molecular structure of these polymers consists of long, non-metallic chains with strong covalent bonds that resist the movement of heat energy through the material. Unlike metals, which have free electrons that conduct heat efficiently, polymers lack these free electrons, significantly reducing thermal conductivity. Additionally, the incorporation of additives, fillers, or foaming agents can further reduce the material's ability to conduct heat by creating insulating air pockets or by scattering heat energy. The inherently low density of polymers, combined with their non-metallic atomic structure, makes them naturally low in thermal conductivity, which is why they are used as insulators in industries requiring thermal management.

Key factors to consider for low thermal conductivity polymer fasteners

Low thermal conductivity polymer fasteners provide excellent thermal insulation, reducing heat transfer between components, which is crucial for thermal management in industries like electronics, automotive, and aerospace. They improve energy efficiency by minimizing heat loss or gain and protect heat-sensitive components, extending the lifespan of electronics and machinery. These fasteners are also lightweight, making them ideal for weight-sensitive applications, and offer added benefits like corrosion resistance, ensuring durability and long-term performance in harsh environments. Their combination of thermal insulation, lightweight design, and durability makes them highly valuable for efficient thermal management.

What other attributes do low thermal conductive polymers poses?

Low thermal conductive polymer fasteners offer additional attributes like excellent electrical insulation, making them ideal for electronics and electrical systems where both thermal and electrical isolation are needed. They provide strong chemical and corrosion resistance, ensuring durability in harsh environments like automotive, aerospace, and chemical processing. Their lightweight nature reduces system weight, improving fuel efficiency, particularly in aerospace and automotive industries. Additionally, these fasteners offer flexibility and vibration dampening, reducing wear in high-vibration environments. These combined properties make them highly suited for industries that require durability, efficiency, and long-term performance under demanding conditions.

Low thermal conductivity polymer screws, nuts, bolts, washers, and fasteners are fasteners that are made from polymers that have a low ability to conduct heat. They are used in a variety of applications where thermal management is a concern, such as in the electronics and automotive industries, or in environments where heat needs to be isolated or dissipated.

There are a variety of low thermal conductivity polymers that can be used to make screws, nuts, bolts, washers, and fasteners, including polyethylene, polypropylene, and polytetrafluoroethylene (PTFE). These polymers are known for their low thermal conductivity, which makes them suitable for use in applications where thermal management is a concern.

Low thermal conductivity polymer screws, nuts, bolts, washers, and fasteners may be used in a variety of applications where thermal management is a concern, such as in the construction of electronic devices or in the assembly of mechanical components. They may also be used in the manufacture of insulation materials or in the installation of heating and cooling systems.

Low thermal conductivity polymer fasteners are often chosen for their low thermal conductivity, as well as their other beneficial properties, such as corrosion resistance and good mechanical properties. They can help to improve the performance and reliability of equipment and systems in environments where thermal management is a concern, and they can help to prevent overheating or to dissipate heat effectively.

Overall, low thermal conductivity polymer screws, nuts, bolts, washers, and fasteners are an important component in the oil & gas industry as well as many others.