119 Products

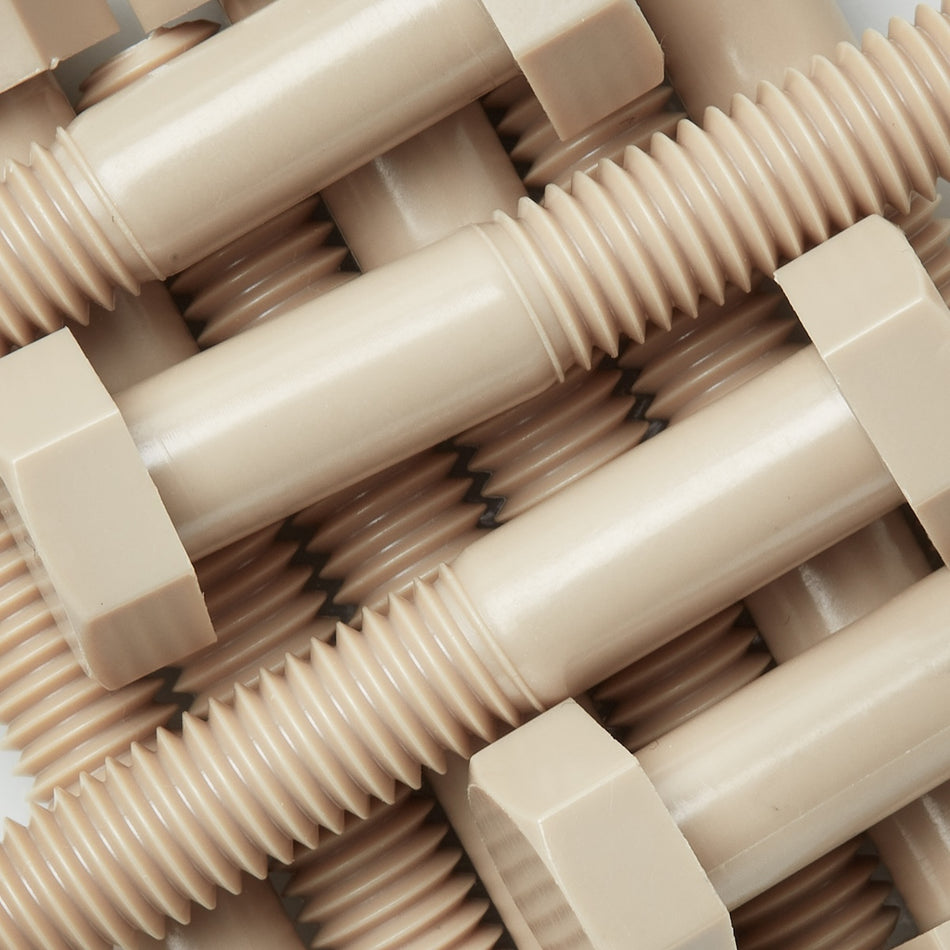

Oil and Gas Industry's use of Polymer Screws, Nuts, Bolts, and Fasteners

The oil and gas industry often uses polymer screws, nuts, bolts, and fasteners in a variety of applications, including the construction and maintenance of drilling rigs, pipelines, and other infrastructure.

Polymer screws, nuts, and bolts are made from synthetic materials, such as plastic or rubber, and are often used in situations where metal fasteners may not be suitable. For example, polymer fasteners can be used in corrosive environments, where metal fasteners may rust or degrade over time. They can also be used in situations where weight or electrical conductivity is a concern, as they are typically lighter and non-conductive compared to metal fasteners.

In the oil and gas industry, polymer fasteners may be used in a variety of applications, including:

-

Sealing and insulation: Polymer fasteners can be used to seal joints and connections in pipelines and other infrastructure, helping to prevent leaks and maintain pressure. They can also be used to insulate electrical connections, helping to prevent electrical shocks and protect against interference.

-

Vibration damping: Polymer fasteners can be used to secure equipment in situations where vibration is a concern, such as on drilling rigs or in offshore platforms. They can help to reduce the transmission of vibrations, which can help to prolong the life of the equipment and improve its performance.

-

Low-temperature applications: Polymer fasteners can be used in low-temperature environments, such as offshore platforms in cold climates, where metal fasteners may become brittle and break.

Overall, polymer screws, nuts, bolts, and fasteners can be a useful alternative to metal fasteners in the oil and gas industry, offering a range of benefits including corrosion resistance, insulation, vibration damping, and low-temperature performance.

The oil and gas industry involves the exploration, extraction, refinement, and distribution of fossil fuel resources, primarily oil and natural gas. These resources are used to generate electricity, heat homes and buildings, fuel vehicles and aircraft, and serve as raw materials for a variety of products, including plastics and chemicals.

The exploration phase of the industry involves searching for deposits of oil and natural gas, which can be found in a variety of geological formations, including underground reservoirs, offshore platforms, and shale formations. Once a deposit has been located, the extraction phase begins, which involves drilling wells to access the oil or gas and pumping it to the surface.

After the oil or gas has been extracted, it is transported to a refinery where it is processed and refined into various products, such as gasoline, diesel, and propane. These refined products are then distributed to markets around the world through pipelines, tanker ships, and other means of transportation.

The oil and gas industry is a major contributor to the global economy and is essential to many aspects of modern life. However, the extraction and use of fossil fuels also has significant environmental impacts, including air pollution, water pollution, and greenhouse gas emissions, which contribute to climate change. As a result, there has been increasing focus on developing and using alternative energy sources that have a lower environmental impact.