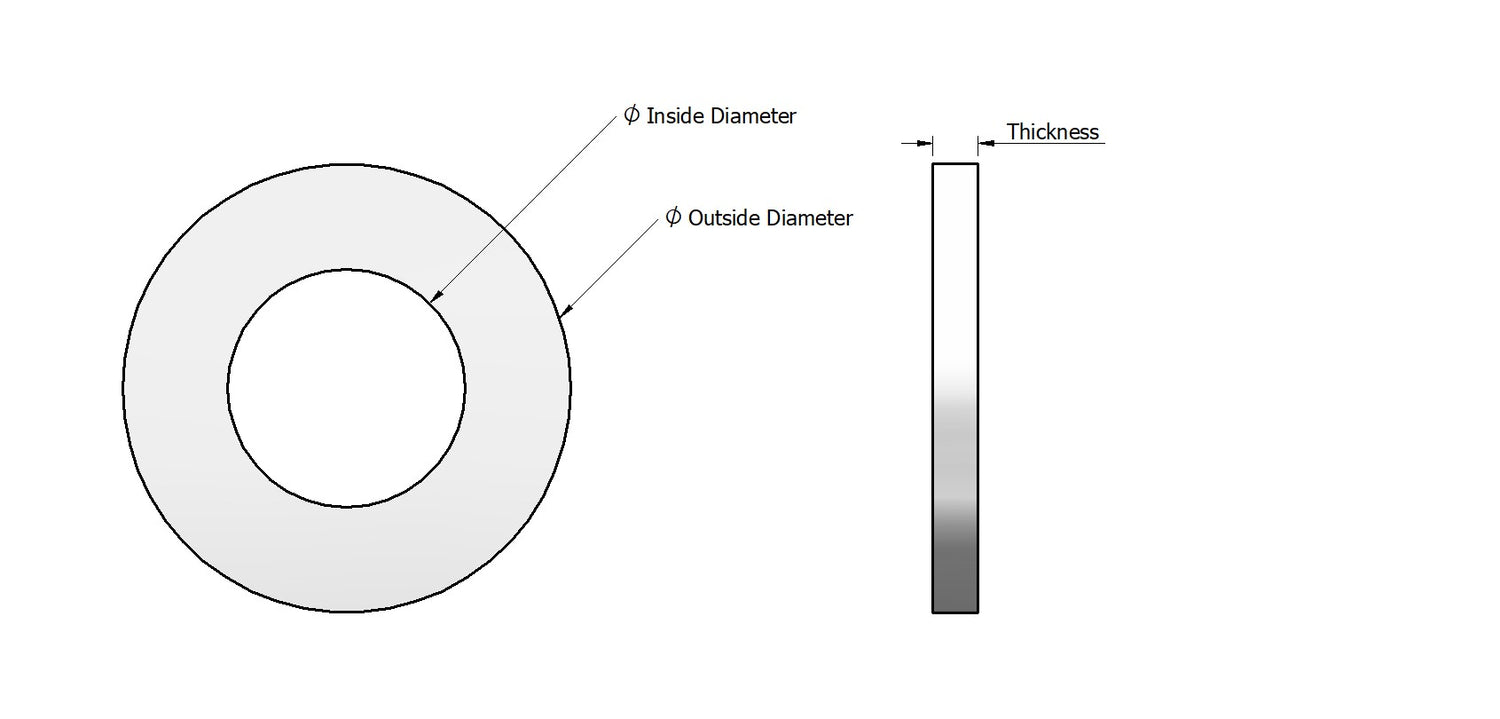

Polyslider Composite Graphite Flat Washers - DIN 125 A

Polyslider Composite Graphite Flat Washers - DIN 125 A

Volume Discounts Available:

Show more Show less

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material:

Measurement System: Metric

Colour: Grey/Natural

Polyslider Composite Graphite Flat Washers - DIN 125 A conform to the following Standards/Norms:

DIN 125 A

Polyslider flat washers are engineered using a sophisticated material composition that involves a polyamide base in which graphite particles are uniformly distributed. This unique manufacturing process results in the formation of oblate graphite layers on the top surface, a characteristic that significantly enhances the washer's performance by reducing friction and wear.

The key advantage of these washers is their exceptional resistance to creep deformation under surface pressure. Creep deformation, a phenomenon where material gradually deforms under a constant stress, can severely affect the longevity and functionality of mechanical components. However, Polyslider flat washers, with their advanced material composition, offer superior creep resistance, ensuring stable performance even in challenging conditions.

Additionally, the excellent friction and abrasion characteristics of Polyslider flat washers make them highly suitable for applications across various types of equipment as thrust washers. In such roles, they are crucial for supporting axial loads while minimising friction between moving parts. This property is particularly beneficial in ensuring the durability and efficiency of machinery, leading to reduced maintenance needs and longer operational lifespans.

The utilisation of Polyslider flat washers in equipment parts underscores their value in industrial and mechanical applications where reliable, high-performance components are essential. Their ability to maintain structural integrity, resist wear, and perform under significant stress positions them as a premium choice for manufacturers seeking to enhance the quality and durability of their products.

The data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.