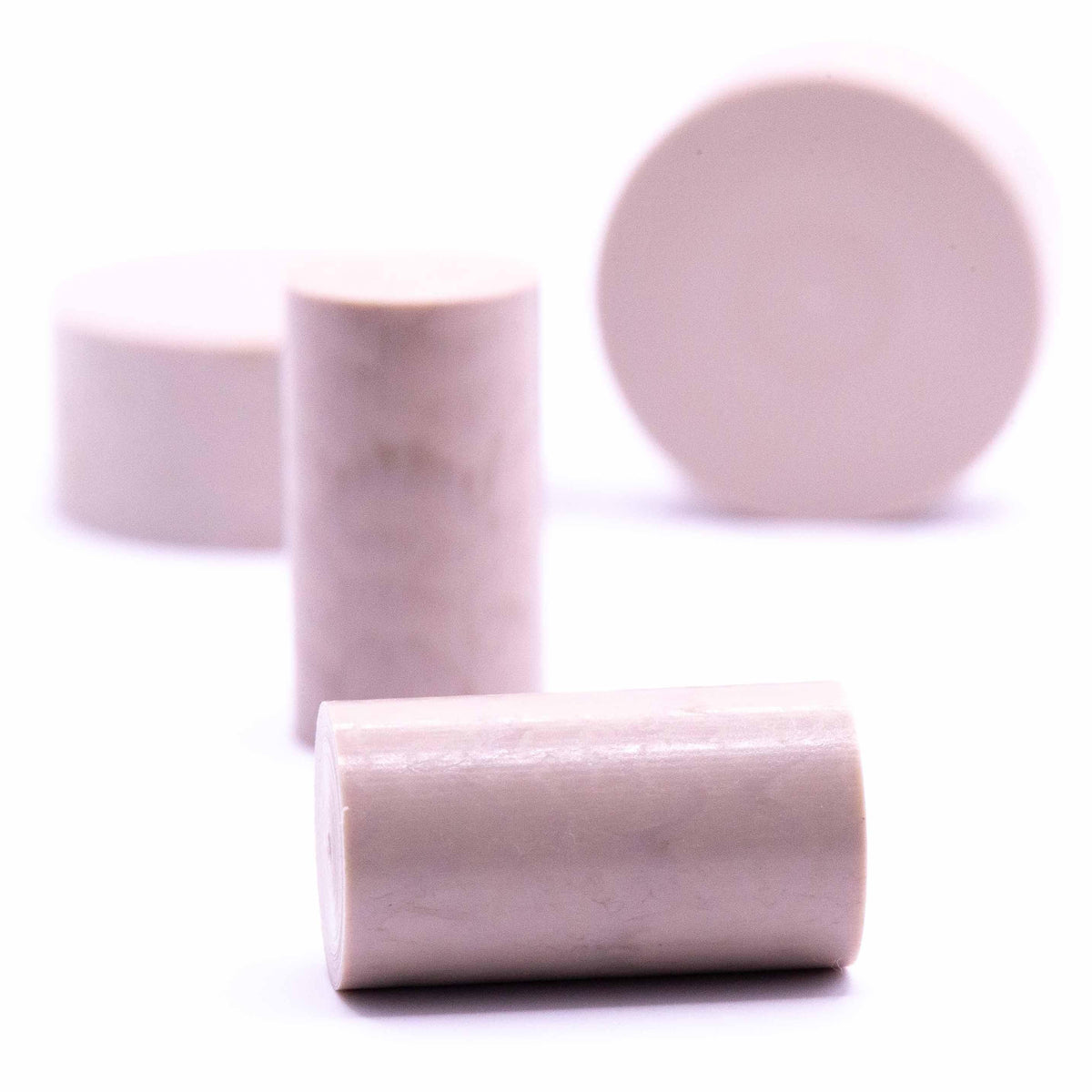

PEEK Natural 450G Rod

PEEK Natural 450G Rod

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

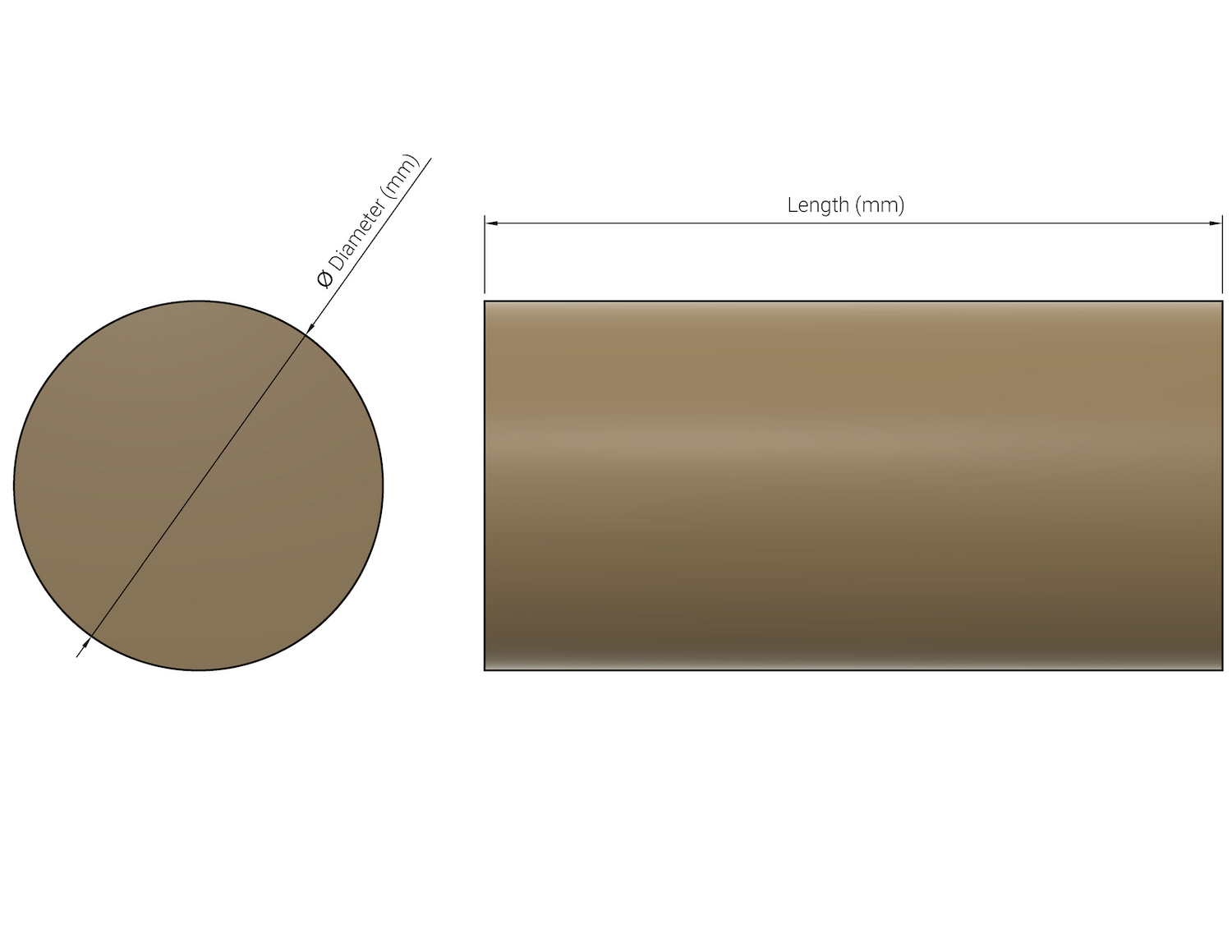

Material: PEEK

Measurement System: Metric

Colour: Natural/Beige

Maximum Temperature: 260°C/500°F

Flammability: UL94 V-0

PEEK Natural 450G Rod conform to the following Standards/Norms:

Our unfilled PEEK Rod/Bar is manufactured exclusively from Victrex 450G material.

We provide cutting and precision grinding on request, please get in touch to discuss this further.

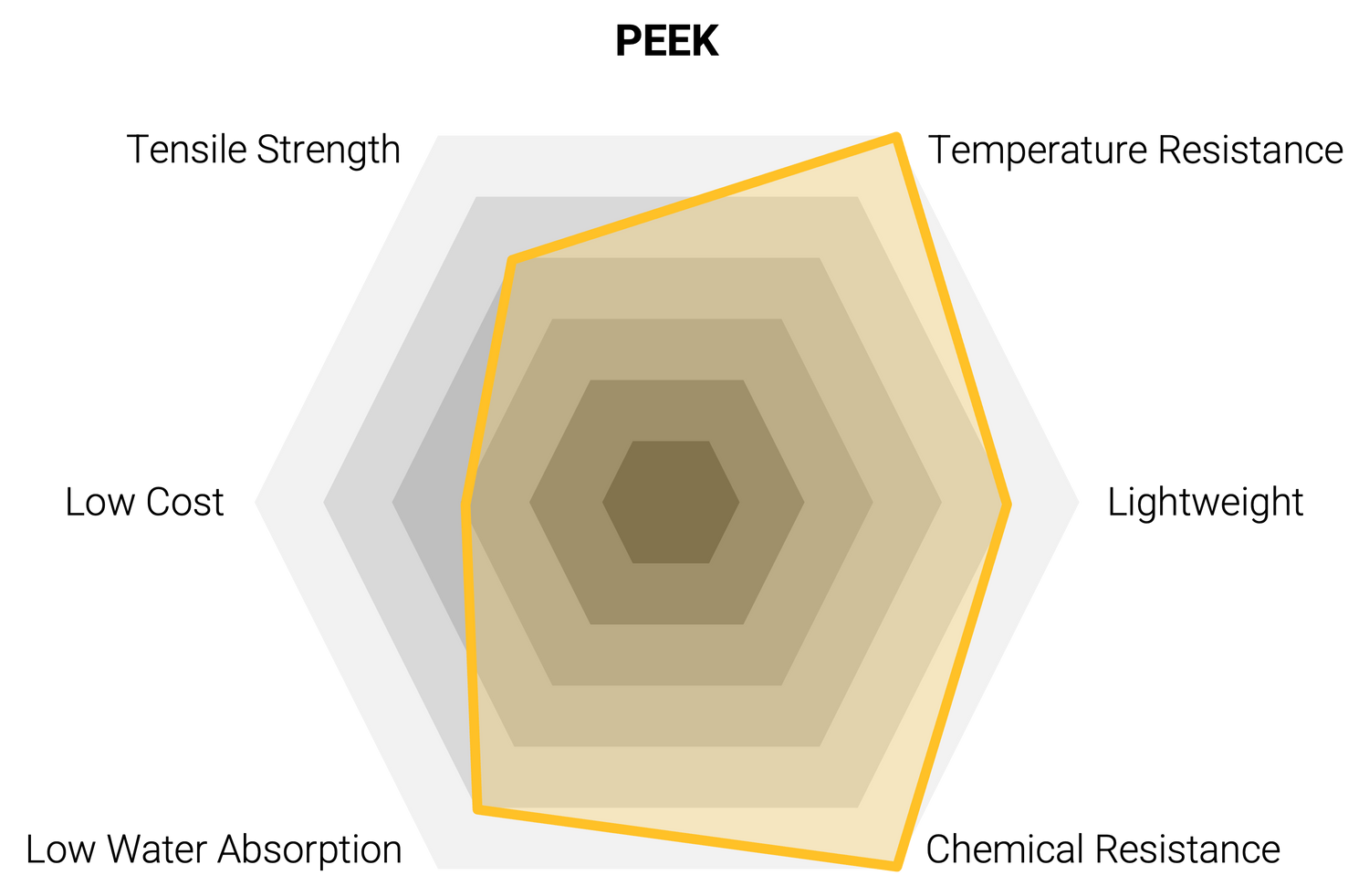

PEEK (Polyetheretherketone) is a high-performance thermoplastic polymer that offers exceptional mechanical, thermal, and chemical properties. PEEK 450g refers to a specific grade of unfilled PEEK material developed by Victrex, and is available in various lengths and diameter rods.

PEEK 450g rods are known for their excellent heat resistance, high tensile strength, low friction coefficient, and resistance to chemicals, making them suitable for a wide range of applications. These rods are produced through extrusion processes and are available in various diameters and lengths to meet specific machining requirements.

PEEK Rod provides a great starting point for the manufacture of components through machining. Here are some common machining processes used for PEEK 450g rods:

Cutting: PEEK can be cut using conventional cutting tools such as high-speed steel (HSS) or carbide tools. Carbide tools are preferred for their higher hardness and heat resistance. It's important to use sharp tools to minimize heat generation during cutting.

Turning: PEEK can be turned on a lathe to create cylindrical shapes. A slow cutting speed and moderate feed rate are recommended to avoid excessive heat buildup. Using coolant or air blast during turning helps to dissipate heat and prolong tool life.

Milling: PEEK can be milled using end mills or other milling cutters. It's essential to use tools with sharp edges and low cutting forces to prevent melting or burr formation. Coolant or compressed air can be used to cool the tool and workpiece during milling.

Drilling: PEEK can be drilled using standard twist drills or specialized carbide drills designed for high-temperature materials. Using a pecking technique (drilling in short, intermittent cycles) helps to evacuate chips and reduce heat build-up.

PEEK 450g rods find applications in industries such as aerospace, automotive, medical, electronics, and oil and gas. Some common uses include:

Aerospace components: PEEK rods are used for manufacturing various aircraft components, including structural parts, bearings, bushings, and seals, thanks to their lightweight and high strength-to-weight ratio.

Medical implants: PEEK is biocompatible and resistant to sterilization methods like autoclaving, making it suitable for medical implants such as spinal cages, orthopedic implants, and dental components.

Electrical insulation: PEEK's excellent electrical insulation properties make it useful for electrical connectors, insulators, and coil forms.

Seals and gaskets: PEEK's chemical resistance and low friction coefficient make it ideal for sealing applications in chemical processing, oil and gas, and automotive industries.

Food processing equipment: PEEK's resistance to chemicals, wear, and high temperatures make it suitable for components used in food processing machinery.

Victrex 450G is a premium PEEK material compared to other alternatives and is the go to grade of PEEK for the aerospace industry. Exceptional properties and versatility make it a preferred choice for demanding applications where reliability and performance are crucial.

The PEEK data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

Key Polyether Ether Ketone (PEEK) Properties

Polyether Ether Ketone (PEEK) Datasheet

Follow the link below to view our PEEK data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

PEEK Key Properties

Why Choose High Performance Polymer?

-

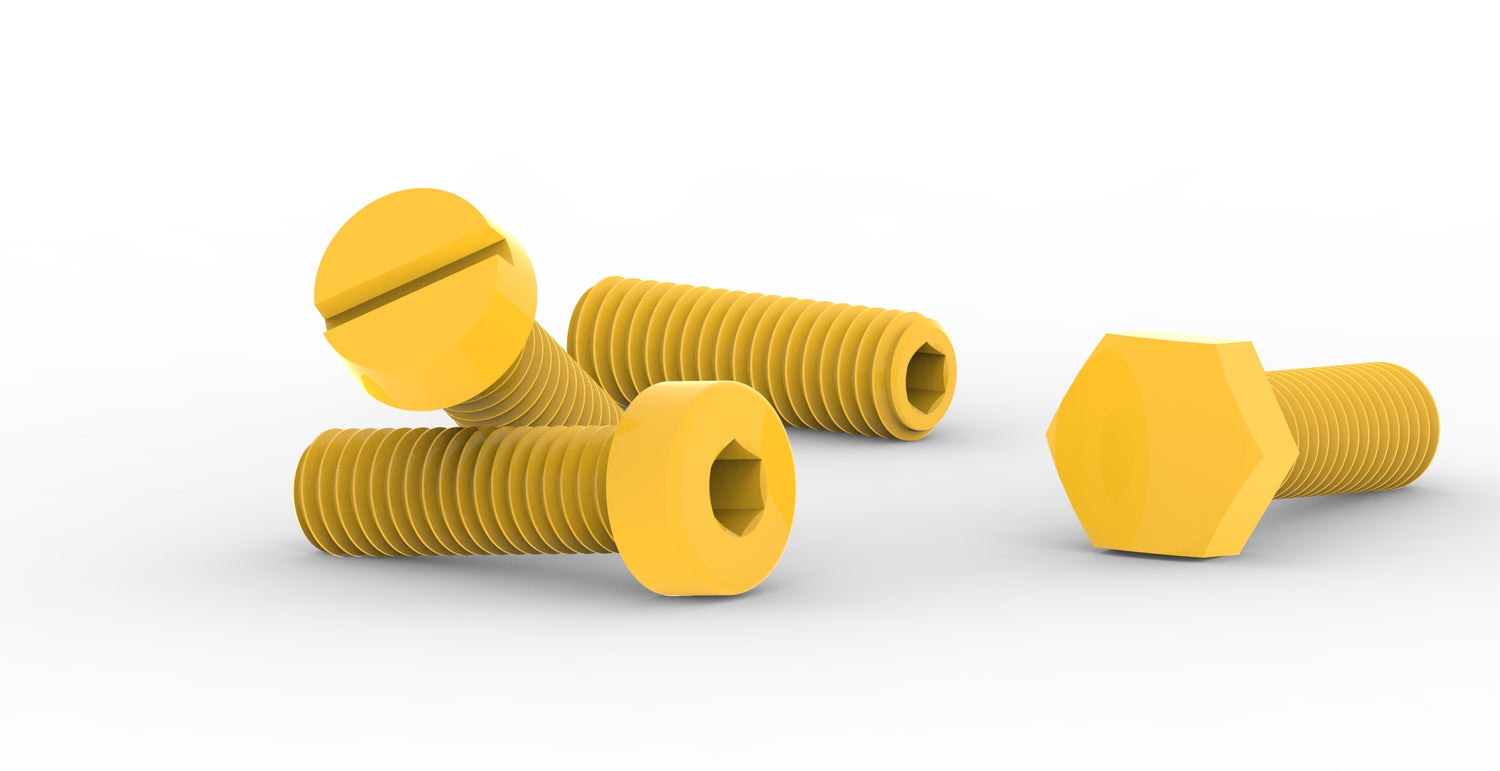

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.