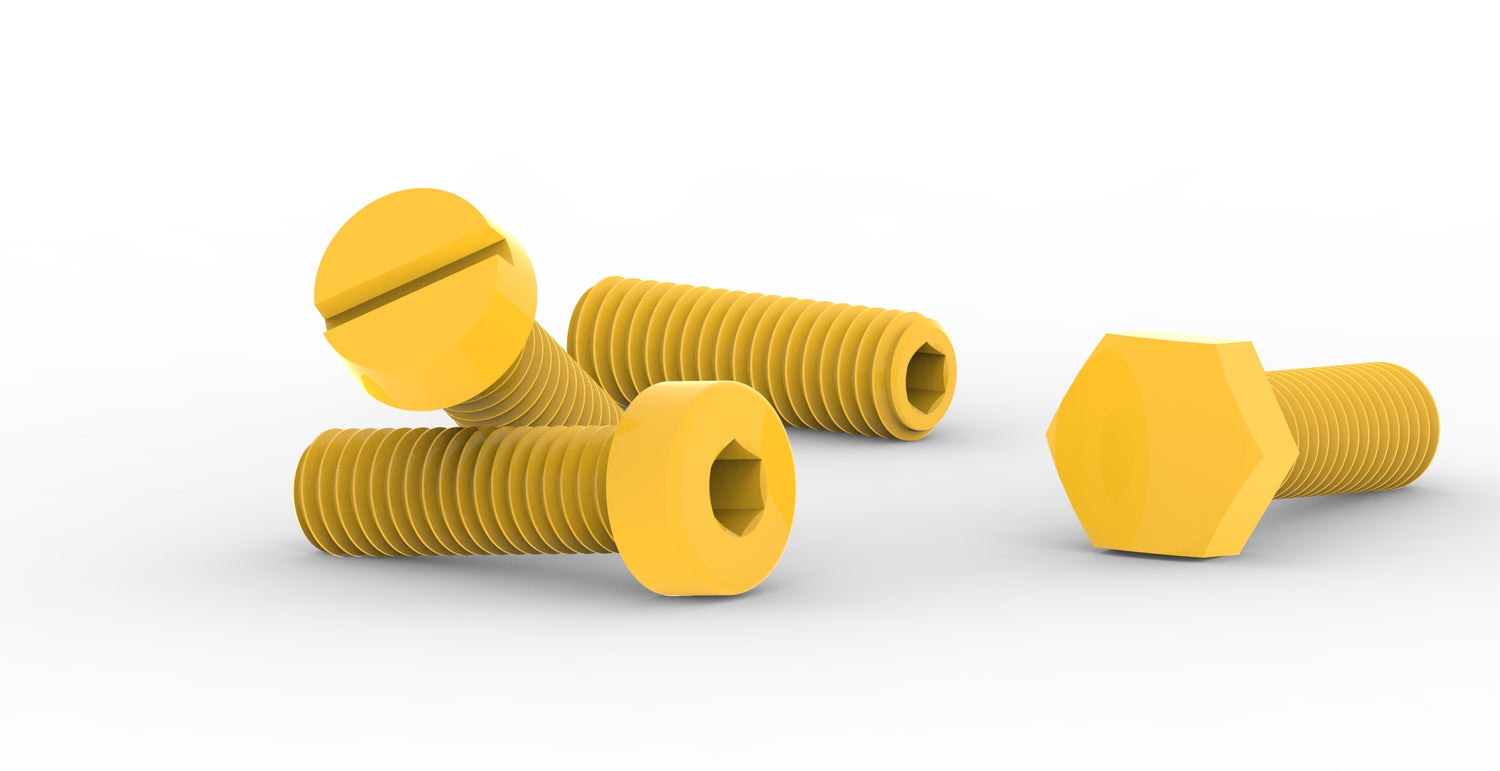

Nylon Slotted Grub Screws - DIN 551

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

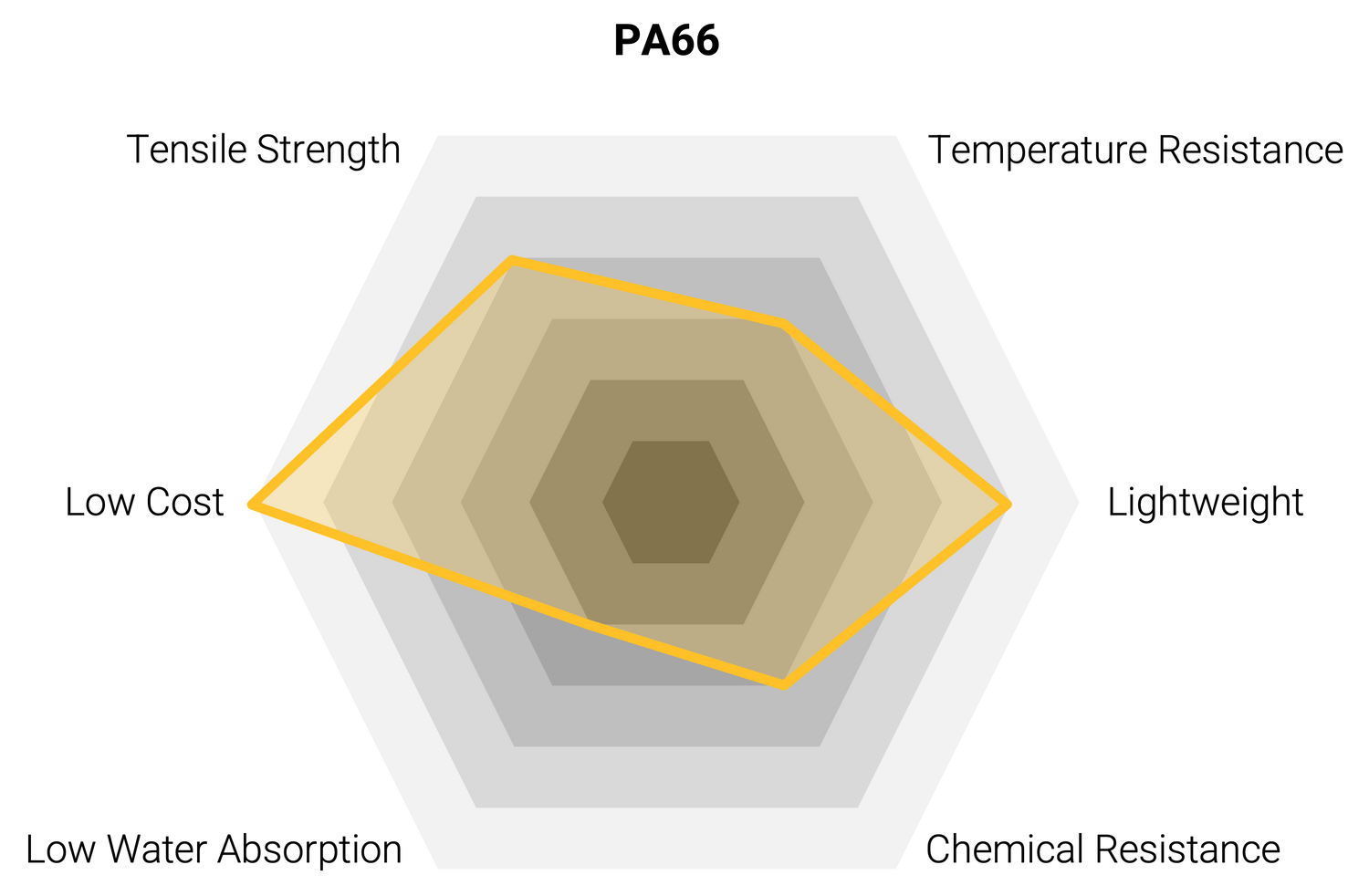

Material: PA66

Measurement System: Metric

Drive Type: Slotted

White

Continuous use temperature: 100°C Maximum temperature: 170°C

Flammability UL94 HB

Nylon Slotted Grub Screws - DIN 551 conform to the following Standards/Norms:

ISO 4766

DIN 551

CSN 021181

PN 82272

UNI 4766

Our nylon slotted grub screws feature a headless design with a straight slot drive, allowing for flush or recessed installation using a flat-bladed screwdriver. Conforming to DIN 551 specifications, they are typically used in applications requiring secure axial positioning of components without protruding hardware, making them ideal for compact assemblies and surface-sensitive systems.

Applications

Nylon slotted grub screws are frequently used in fine mechanical systems, electronics, and laboratory instruments. Their non-conductive, non-magnetic properties make them highly suitable for securing shafts, collars, and rotating parts in electrical or RF-sensitive equipment. These fasteners are often specified in adjustment points or calibration mechanisms in optical, medical, and metrology devices, where minimal thread damage and repeatable load control are essential.

Their usage includes lightweight structural assemblies, insulating hardware for PCB mounting, and plastic-to-plastic fastening, where their chemical resistance and low abrasion characteristics help maintain long-term reliability. They deliver excellent mechanical strength, low water absorption, and dimensional stability across a broad temperature range. These screws also exhibit good resistance to oils, fuels, and most industrial solvents, making them suitable for demanding environments.

Whether your system requires a lightweight locking component, a corrosion-proof positioning screw, or an electrically neutral adjustment point, HPP’s nylon slotted grub screws offer an engineered solution for technical and specialist fastening applications.

The PA66 data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

PA66 Key Properties

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.