2 Products

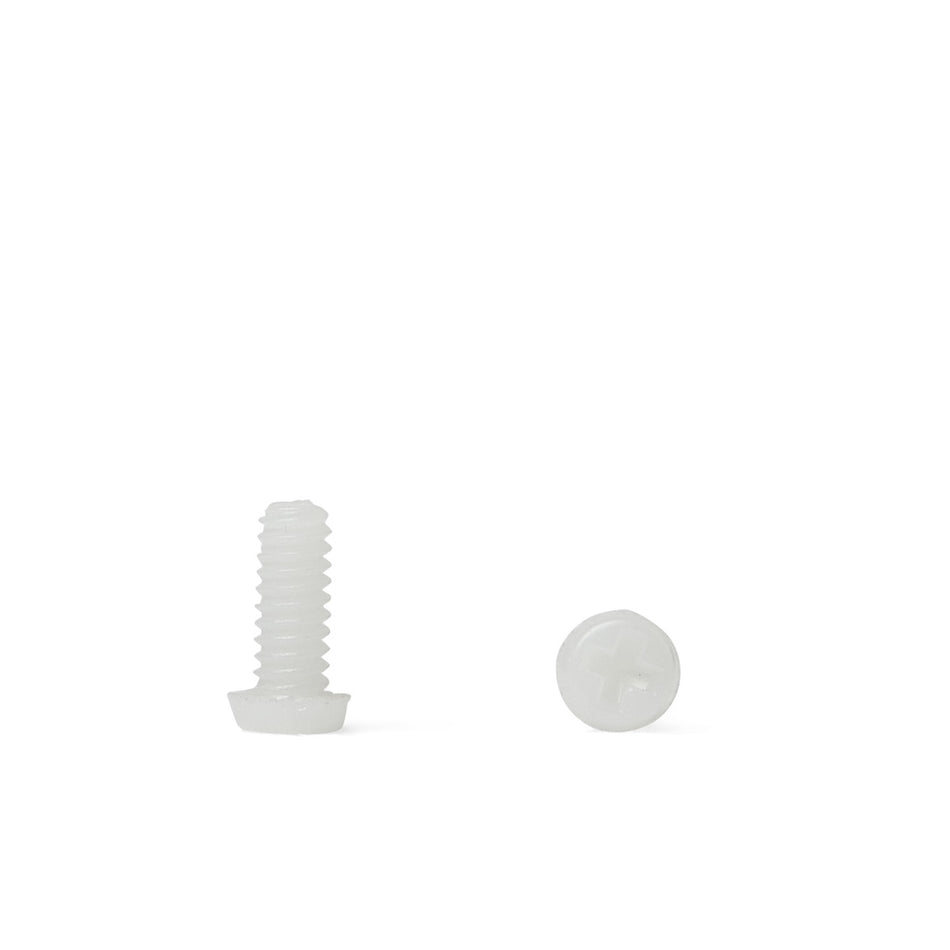

RENY screws are used frequently in multiple industries worldwide. It was developed by the Mitsubishi Gas Chemical Company and as its title states is mainly based on polyamide MXD6 (PAMXD6).

RENY’s structure has similar properties to common nylon screws, however it is reinforced with 50% glass-fibre, which makes it one of the highest tensile strength polymer screws on the market. RENY also excels in oil resistance, which makes it a common sight within the automotive industry.

M1.2 screws, bolts, nuts, and washers made of polymer or plastic materials may be used in a variety of applications where a lightweight and corrosion-resistant fastener is needed. Some possible uses for these fasteners include:

-

Electronic devices: M1.2 screws and fasteners made of plastic or polymer materials may be used in the assembly of electronic devices such as laptops, smartphones, and tablets. These materials are often chosen for their lightweight and corrosion-resistant properties, making them suitable for use in electronic devices that may be subject to moisture or other environmental conditions.

-

Automotive components: Plastic or polymer M1.2 screws and fasteners may be used in the manufacture and assembly of automotive components such as engine covers, air intake systems, and fuel systems. These materials can withstand high temperatures and are resistant to corrosion, making them suitable for use in the harsh environments found in vehicles.

-

Medical devices: M1.2 screws and fasteners made of plastic or polymer materials may be used in the manufacture and assembly of medical devices such as patient monitors, ventilators, and diagnostic equipment. These materials are often chosen for their biocompatibility and corrosion-resistant properties, making them suitable for use in medical applications.